Four Axis Infrared Bridge Cutting Machine With Spindle

Four axis infrared bridge cutting machine with spindle is widely suitable for processing granite, marble, artificial stone, slab and other types of stone. The machine head can swing at any angle and can cut the plate at any angle and shape.And the stone cutting machine can also cut the large plate with 45°chamfering, opening the basin hole, stove hole, and diagonal cutting.

Model:CX-3220

Send Inquiry

Product Description

Four Axis Infrared Bridge Cutting Machine With Spindle

Product Feature:

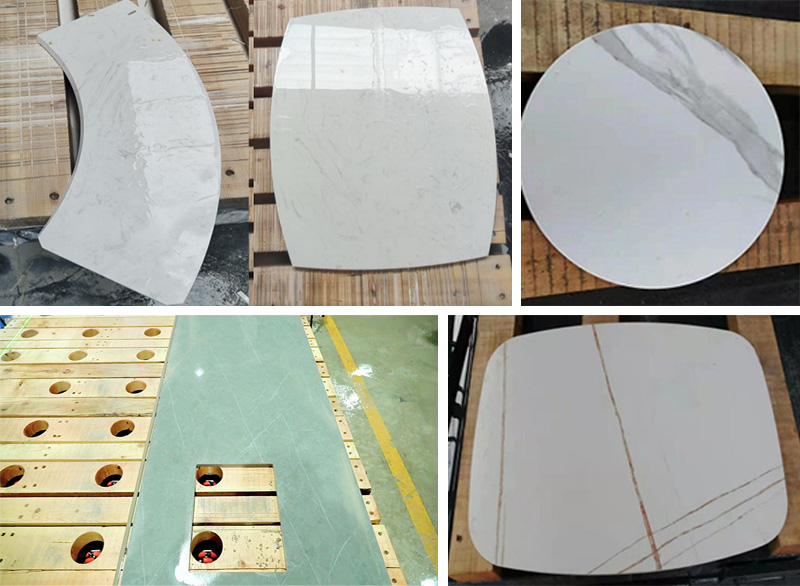

1. The machine head can swing at any angle and can cut the plate at any angle and shape: horizontal cutting, longitudinal cutting, arc cutting, elliptical cutting, and round cutting. The machine can also be used for bump edging.

2. In addition to the cutting shape, it can also cut the large plate with 45° chamfering, opening the basin hole, stove hole, and diagonal cutting

3. The platform can be turned by 85°, which is convenient for loading and unloading.

4. No complicated operations, just input data on the control system

Equipped with a grinding wheel device, which can polish the table hole and cutting surface.

Detail Image:

Specification:

|

Model |

Four Axis Infrared Bridge Cutting Machine With Spindle |

|

Processing size: X-axis |

Horizontal dimension 3200mm |

|

Processing size: Y axis |

Longitudinal dimension 2000mm |

|

Blade diameter |

350mm |

|

Bed Frame |

Seamless welding, aging treatment, five-sided milling machine processing |

|

Surface treatment |

High temperature plastic spraying to prevent paint from falling off |

|

Cutting thickness |

Within 50mm |

|

Control System |

Chengdu 70 four-axis custom control system |

|

Platform flap angle |

0-85 degrees |

|

Head rotation angle |

0-360 degrees |

|

Nose Tilt Angle |

45 degree |

|

Attached spindle power |

7.5kw high-speed spindle, up to 0 to 24000 rpm |

|

With spindle inverter |

7.5kw inverter |

|

Workbench |

Hydraulic lifting, thickened wooden table, increased pneumatic pressure plate |

|

Programmatically |

Modify data directly in the operating system |

|

Cutting motor |

Dedicated 11KW cutting motor, waterproof and high temperature resistant |

|

Cutting speed |

0-3000mm/mim according to stone thickness |

|

Transfer method |

rack drive |

|

Drive mode |

Taiwan imported 30 square rail + imported high precision 3210 ball screw |

|

Control method |

5 sets of Eura high-precision 1.3 kW pure servo control acceleration and deceleration machine |

|

Appendix |

A hydraulic station, a quartz stone saw blade |

|

Lubrication |

Electric automatic oil filling |

|

Packing |

Plastic packaging (stretch film pearl cotton) |

|

Size |

Length 5700mm Width 3230mm Height 3000mm |

|

Weight |

about 4 tons |

It is suitable for cutting, cross-cutting, longitudinal cutting, chamfering, rounding and other special-shaped processing of granite, marble slabs, artificial stone, rock slabs and other types of stone.