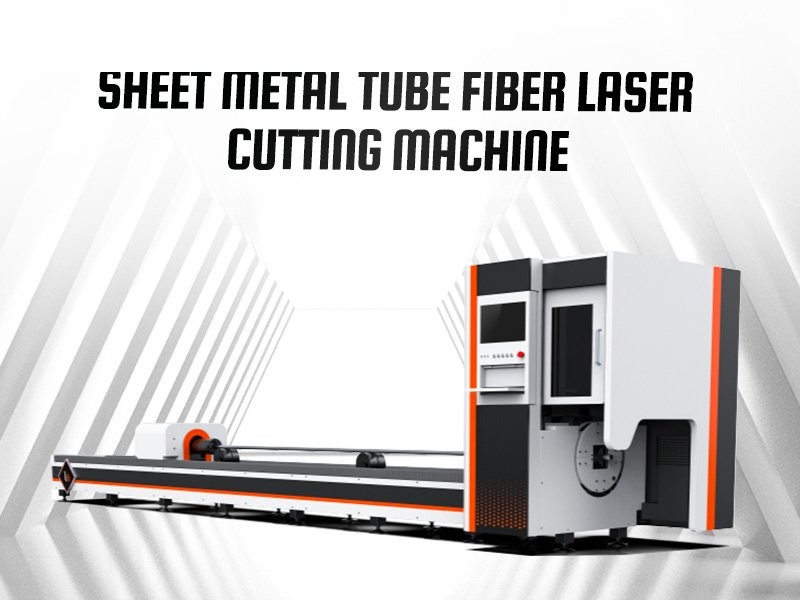

1500S Laser Tube Cutting Machine

The device is easy to clamp and labor-saving, with four linkage dual chucks that do not damage the pipe or cause scratches, ensuring smooth feed and cutting accuracy.

Model:CX-1500S

Send Inquiry

Product Description

Advantage:

The system does not require drawing, only the input of pipe cutting parameters is needed, and the operation is simple and clear.

All operations have menus or graphical prompts, making them user-friendly. All button switches are designed with humanization, comfortable and convenient.

The conventional effective processing length of the pipe is 6 meters, and the body can be divided into 2 sections for easy handling. The size can be customized.

The device is easy to clamp and labor-saving, with four linkage dual chucks that do not damage the pipe or cause scratches, ensuring smooth feed and cutting accuracy.

Specification:

|

Model |

CX-1500S |

|

Laser source |

1500S |

|

Laser head |

Gangchun |

|

Water chiller |

1500S |

|

Control system |

Fangling LX4510H |

|

Servo motor |

Y750W, A750W+400W,Z400W |

|

Tube type |

Square tube, round tube, rectangular tube, elliptical tube, angle iron |

|

diameter |

10-108mm |

|

thickness |

3mm(up to the laser source) |

|

speed |

0-8000mm/min |

|

cutting precision |

±0.2 mm(Depending on factors such as workpiece type, pre-processing condition) |

|

repeat precision |

±0.01mm |

|

Gas |

Air |

|

driving mode |

rack |

|

guid rail |

Precision square guide rail |

|

chunk |

manual |

|

loading mode |

Manual uploading and automatic cutting |

|

tail length |

About 12cm |

|

Size |

6600mm*830mm*1330mm |

|

Packing Size |

4200*1100*1430mm |

|

Weight |

470KG |

|

Power |

220V/50HZ |

It can be applied to stainless steel, carbon steel, aluminum alloy, copper, various alloys, and rare metals. Suitable for square tubes, round tubes, rectangular tubes, oval tubes, and angle iron.